New Multiair Technology: More Power, Less Fuel, Lower Emissions

Already a world leader in advanced diesel engine technology, Fiat Group has just launched MultiAir, a fundamental breakthrough in petrol engine design that will dramatically cut fuel consumption, as well as significantly boosting power and torque, cutting carbon dioxide emissions by between 10 and 25 per cent, and up to a 60 per cent reduction in other engine pollutants.

With two generations of common rail direct injection diesel engine technology, UniJet and MultiJet, to its credit, Fiat has dramatically improved diesel engine performance, economy and emissions. Now, with MultiAir, Fiat has brought together the company's enviable expertise and technology to make one of the single largest leaps forward for petrol engine design in recent times.

In short, an engine equipped with Fiat MultiAir technology is more powerful, more responsive across the entire engine speed range, uses considerably less fuel, and reduces all types of exhaust emissions by a substantial amount. It will also assist in enabling Fiat to maintain its lead in low emissions and low fuel consumption technology, which has seen Fiat crowned for the past two years as the number one car maker for the lowest range-wide CO2 emissions.

The first new engine to be equipped with MultiAir will be the 16-valve 1.4 litre family of naturally aspirated and turbocharged engines, and the first car to go on sale with MultiAir installed will be the Alfa MiTo at the end of 2009. Its second application will be as an integral part of a new two cylinder engine family.

Development of the Fiat MultiAir system

In the last decade, the development of Common Rail technology for diesel engines marked a breakthrough in the passenger car market. To be equally competitive in the field of petrol engines, Fiat Group decided to follow the same approach and focus on breakthrough technologies.

The aim was to provide customers with substantial benefits in terms of fuel economy and driving pleasure, while maintaining the engine's intrinsic refinement, based on a smooth combustion process and on light structures and components.

The key parameter to control diesel engine combustion and therefore performance, emissions and fuel consumption, is the quantity and characteristics of the fuel injected into the cylinders. That is the reason why the Common Rail electronic diesel fuel injection system was such a fundamental breakthrough in direct injection diesel engine technology.

However, the key to controlling petrol engine combustion, and therefore performance, emissions and fuel consumption, is the quantity and characteristics of the fresh air charge in the cylinders. In conventional petrol engines the air mass trapped in the cylinders is controlled by keeping the intake valve opening constant and adjusting upstream pressure through a throttle valve. One of the drawbacks of this simple conventional mechanical control is that the engine wastes about 10 per cent of the input energy in pumping the air charge from a lower intake pressure to the atmospheric exhaust pressure.

A fundamental breakthrough in air mass control, and therefore in petrol engine technology, is based on direct air charge metering at the cylinder inlet ports by means of advanced electronic actuation and control of the intake valves, while maintaining a constant natural upstream pressure.

Research on this key technology started in the '80s, when engine electronic control reached the stage of a mature technology.

At the outset, world-wide research efforts were focused on the electromagnetic actuation concept, by which valve opening and closing is obtained by alternatively energising upper and lower magnets with an armature connected to the valve. This actuating principle had the intrinsic appeal of maximum flexibility and dynamic response in valve control, but despite a decade of significant development efforts, the main drawbacks of the concept – it being intrinsically not fail-safe and its high energy absorption – could not be fully overcome.

At this point most automotive companies fell back on the development of the simpler, robust and well-known electromechanical concepts, based on valve lift variation through dedicated mechanisms, usually combined with camshaft phasers to allow control of both valve lift and phase.

The main limitation of these systems is low flexibility in valve opening schedules and a much lower dynamic response; for example, all the cylinders of an engine bank are actuated simultaneously, thereby excluding any cylinder selective actions. Many similar electromechanical valve control systems were subsequently introduced over the past decade.

In the mid '90s, Fiat Group research efforts switched to electro-hydraulic actuation, leveraging on the know-how gained during its Common Rail development. The goal was to reach the desired flexibility of valve opening schedule air mass control on a cylinder-by-cylinder and stroke-by-stroke basis.

The electro-hydraulic variable valve actuation technology developed by Fiat was selected for its relative simplicity, low power requirements, intrinsic fail-safe nature and low cost potential.

Fiat MultiAir Technology: how it works

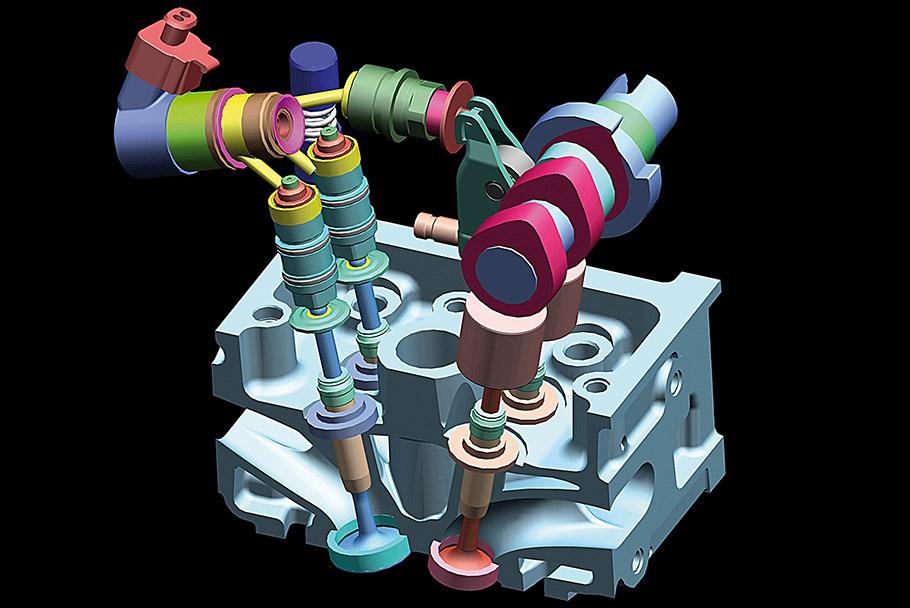

The operating principle of the system, applied to intake valves, is the following: a piston, moved by a mechanical intake camshaft, is connected to the intake valve through a hydraulic chamber, which is controlled by a normally open on/off solenoid valve.

When the solenoid valve is closed, the oil in the hydraulic chamber behaves like a solid body and transmits to the intake valves the lift schedule imposed by the mechanical intake camshaft.

When the solenoid valve is open, the hydraulic chamber and the intake valves are de-coupled; the intake valves do not follow the intake camshaft anymore and close under the valve spring action.

The final part of the valve closing stroke is controlled by a dedicated hydraulic brake, to ensure a soft and regular landing phase in any engine operating conditions.

Through solenoid valve opening and closing time control, a wide range of optimum intake valve opening schedules can be easily obtained.

For maximum power, the solenoid valve is always closed and full valve opening is achieved following completely the mechanical camshaft, which is specifically designed to maximise power at high engine speed (long opening time).

For low-rpm torque, the solenoid valve is opened near the end of the camshaft profile, leading to early intake valve closing. This eliminates unwanted backflow into the manifold and maximises the air mass trapped in the cylinders.

In engine part-load, the solenoid valve is opened earlier, causing partial valve openings to control the trapped air mass as a function of the required torque.

Alternatively the intake valves can be partially opened by closing the solenoid valve once the mechanical camshaft action has already started. In this case the air stream into the cylinder is faster and results in higher in-cylinder turbulence.

The last two actuation modes can be combined in the same intake stroke, generating a so-called Multilift mode that enhances turbulence and combustion rate at very low loads.

Further Potential of MultiAir Technology

All breakthrough technologies open a new world of further potential benefits, which are usually not fully exploited in the first generation.

Common Rail technology, a Fiat Group worldwide premiere in 1997, paved the way to more than a decade of further technological evolutions such as MultiJet for multiple injections, small diesel engines, and the recent Modular Injection technology, soon to be launched on the market.

Similarly, MultiAir technology, a Fiat worldwide premiere at this month's Geneva Motor Show, (March 2009), will pave the way to further technological evolutions for petrol engines:

- Integration of the MultiAir Direct air mass control with Direct petrol Injection to further improve transient response and fuel economy.

- Introduction of more advanced multiple valve opening strategies to further reduce emissions.

- Innovative engine-turbocharger matching to control trapped air mass through a combination of optimum boost pressure and valve opening strategies.

While electronic petrol injection developed in the '70s and Common Rail developed in the '90s were fuel-specific breakthrough technologies, MultiAir Electronic Valve Control technology can be applied to all internal combustion engines whatever fuel they burn.

MultiAir, initially developed for spark ignition engines burning light fuel ranging from petrol to natural gas and hydrogen, also has wide potential for diesel engine emission reduction.

Intrinsic NOx reduction of up to 60 per cent can be obtained by internal exhaust gas recirculation (iEGR) realised with intake valves reopening during the exhaust stroke, while optimal valve control strategies during cold start and warm-up bring up to 40 per cent HC and CO reduction of emissions. Further substantial reductions come from the more efficient management and regeneration of the diesel particulate filter and NOx storage catalyst, thanks to the highly dynamic air mass flow control during transient engine operation.

Diesel engine performance improvement is similar to that of the petrol engine and is based on the same physical principles. Instead, fuel consumption benefits are limited to few percentage points because of the low pumping losses of diesel engines, one of the reasons for their superior fuel economy.

In the future, powertrain technical evolution might benefit from a progressive unification of petrol and diesel engine designs.

A MultiAir engine cylinder head can therefore be conceived and developed, where both combustion systems can be fully optimised without compromise. The MultiAir electro-hydraulic actuator is physically the same, with minor machining differences, while internal sub-components are all carried over from Fiat's FIRE and SGE applications.