Ford Focus RS (2009)

Ford Focus RS

In the 40-year story of Ford RS, the marque has been applied sparingly, merited by only the most high-performance Ford machines of the time.

Six years have passed since the last Ford RS – the Mk1 Focus RS – finished its strictly limited production run. Now the famous badge has returned for its league of devoted fans and a new generation of performance car enthusiasts.

RS – A Significant Event

This new Focus RS is the product of Ford Team RS, headed by Jost Capito, a committed car enthusiast and racer. Alongside Capito is a small team of dedicated performance car and motorsport engineering specialists, led by Chief Programme Engineer, John Wheeler, whose own expertise stretches over 20 years of Ford performance and motorsport vehicles.

Team RS works hand-in-hand with Ford of Europe experts from across the engineering spectrum to create Ford’s performance road car range. More than 100 engineers have been involved in Focus RS and every one understood the weight of expectation that greets a new Ford RS model.

States Capito: “A new Ford RS is a significant event; the badge is not applied to a new car very often and when it is, it has to be a great car. I know this Focus RS will be thoroughly deserving of the name.”

From early in its development programme, the team set a target to create a car with the poise, power, performance and precision to trade lap times with far more exotic vehicles and be a benchmark for performance and value for money.

Their result is a car capable of lapping the legendary 20.8km (12.3 mile) Nuerburgring Nordschleife repeatedly at speed and equally adept at cruising home afterwards; blending Ford Focus practicality with bespoke engineering, dynamics and a turbocharged, 305PS (300 bhp) 2.5-litre Duratec engine.

Starting Point

Defining performance parameters of the new Focus RS began before the last Mk1 Focus RS left the production line. Perhaps surprisingly, that work didn’t involve the name ‘RS’ at all, for the group was concentrating then on fine tuning the latest Focus ST model.

“In developing Focus ST, we reached 225PS and 320Nm torque with the 2.5-litre Duratec and the outstanding Focus chassis handled it comfortably. This was already 10PS more than the previous Focus RS. ST re-framed what we and our customers could expect of a new RS and it became an excellent development base,” explains John Wheeler.

The team’s other benchmark was the previous-generation Focus RS, and here their own opinions and analysis was augmented by the views of owners.

“We’re in regular contact with RS owners and enthusiasts across Europe and their views helped shape our own. The previous Focus RS was created to give that limited edition, ‘World Rally car for the road’ feel, which made it an extreme experience. We didn’t just want to repeat that formula for new Focus RS and the views and requirements of RS fans were incredibly helpful in creating this car’s everyday side,” Wheeler continues.

The result was a short but complicated set of priorities: the pace and performance feel of the previous RS, but with even more power and greater stability; durable circuit performance, but with greater comfort for everyday driving.

Research work began in earnest, while the timing for introducing the high-performance model was considered. By 2008, Ford of Europe’s flexible manufacturing strategy had created the ability to build low volume vehicles efficiently and there were several key milestones to mark.

“Our flexible manufacturing and the use of shared commodities really helps to produce vehicles like Focus RS, without having to make large manufacturing investments or build off-line,” adds Capito.

“The 2009 production start for Focus RS has marked the 10th anniversary of Ford Focus and 40 years of Ford RS, backed by two consecutive World Rally Manufacturers’ Championship titles. Combined, these factors make the creation of the new Focus RS very appropriate,” he continues.

A Class Apart

Thanks to intensive engineering development from an already high starting point, the new Focus RS will not just be the fastest current Focus model when it goes on sale in early 2009; it will be the fastest and the most powerful front-wheel-drive European Ford ever.

Focus RS is also the only front-wheel-drive, 300+ PS high-performance car available today, an indication of the challenge of creating such a vehicle and the achievements of Ford Team RS in doing so.

“Historically, RS models have been very different in their approaches. Our strategy was to define and create a new RS, with all the characteristics we wanted to see in it, rather than develop a car to compete with anything else already in the market,” says Wheeler.

With the go-ahead to create a new Focus RS, Team RS had already created an impressive benchmark and base in the new Focus ST, so early effort was directed on setting the two cars apart.

Dolphin and Shark

From NVH to design, powertrain to safety, Ford specialists from across the engineering spectrum were involved with Focus RS, needing to understand quickly its requirements and attributes and the differences in philosophy between the ‘ST’ and ‘RS’ brands.

To illustrate the fundamental differences of approach between an ST and an RS, the Team RS engineers created the analogy of ‘Dolphin and Shark’.

Capito explains: “ST and RS should be different animals, as are a dolphin and a shark. Both are highly developed for their roles but have unique characteristics – ST is a balance of performance and refinement, but would not fit the attributes we set for RS and vice versa. It’s surprising how much we used this analogy.”

Those attributes for Focus RS were developed from a definition of “the ultimate production Focus.” In keeping with its heritage, RS is an even more performance-oriented vehicle than ST, developed in every detail with on-track performance of equal importance to on-road behaviour. An exhaustive set of individual criteria was created for every aspect of the car’s performance, dynamics and durability, a process similar in scope to that required for a whole new carline.

However, for all the differences, there is one area of common ground between Focus ST and RS. Both are front-wheel-drive, one of the first decisions taken in the development of RS and explained by Team RS Chief Engineer, Dirk Densing:

“Front-wheel-drive was our preference all along. All-wheel-drive systems add cost, weight, inertia and consequently, fuel consumption. Compensating for the significant weight of an all-wheel-drive system requires dynamic compromises we preferred not to make. If you can achieve the performance you want without steering disturbance, then front-wheel-drive is a better performance car – lighter and with a more precise, linear steering response than AWD. With the work of our advanced research team in Aachen, we were able to achieve this and deliver something genuinely different,” he says.

Great Focus Heritage

In being both a genuine Ford RS and a full member of the Focus family, the new Focus RS represents a significant moment in the legacy of both brands.

The year 2008 marked 10 years since the Ford Focus was first revealed to the world at the Geneva Motor Show in 1998, paving the way for a range of Ford vehicles whose exciting design was matched by class-leading driving quality.

Since this time, more than 5.5 million Ford Focus models have been built in Europe, including Russia, with the car also built and sold in North America, Asia and South Africa.

Now, the latest generation Focus also wears the famous Ford RS badge with pride, continuing a distinguished heritage that can trace its roots back 40 years and encompasses a wide range of Ford models.

“RS is central to Ford’s high-performance heritage and Focus has played a major part in establishing Ford’s excellent reputation for driving dynamics. The all-new Focus RS embraces and celebrates both of these – a genuine RS and a genuine Focus,” concludes Capito.

Focus RS Power

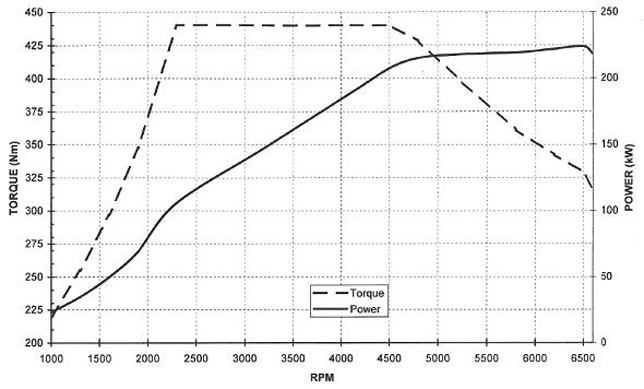

The turbocharged Duratec RS 2.5-litre engine creates Focus RS’ distinctive character, delivering its peak power of 305PS (300 bhp) at 6,500 rpm and peak torque of 440Nm between 2,300 and 4,500 rpm.

Power Generator

The Focus RS engine shares its fundamental structure with that of Focus ST, but there the similarities end. Powertrain manager Len Urwin knew from the beginning that simply adjusting the engine management system for more power would be insufficient for a true RS.

He explains: “There was never an intention to try to ‘chip’ the ST engine. We evaluated several approaches using the ST engine and none gave us the combination of power delivery, character and durability that we wanted, so we opted to create an RS Duratec, using the ST unit as our base.”

The objective was increasing power and torque without affecting durability. To meet that, multiple detail changes were made to the powertrain including a revised cylinder head gasket, ultra-durable metal sprayed cylinder bores, revised pistons and a bespoke camshaft profile and connecting rods, allowing bigger small end bearings.

However, the most obvious changes are the new intake system, exhaust manifold and turbocharger. The larger Borg Warner K16 turbo fitted to Focus RS offers a maximum steady state boost pressure of 1.4 bar – double that of Focus ST’s 0.7 bar – to generate the car’s 35 per cent power increase.

Committed to maintaining responsiveness of the engine, Urwin’s team focused on three areas:

- Integrating the turbo with the exhaust manifold, to allow subtle manifold tuning and strategically locating the turbo in the engine bay, to optimise crash performance and minimise revision to the exhaust system and associated oil and water pipes;

- Carefully sizing the required larger turbo, to closely match the ‘bottom end’ engine responsiveness of Focus ST;

- Reducing the induction system and exhaust losses.

Focus RS needed its own, more aggressive performance character so engineers also modified the torque ‘ramp-up’, to enhance performance feel when on boost.

“While we wanted to be equal on low-end responsiveness and minimise the common off-boost inertia of larger turbos, we didn’t want RS to have the same character as ST,” explains Urwin. “We wanted a stronger feel of increasing boost; we wanted you to really feel the surge of the turbo.”

With the turbo spinning, power arrives quickly. The 305PS peak is reached at 6,500 rpm and holds until the 7,050 rpm redline, to allow full use of the top of the power band. After three seconds at this redline, the engine management system recognises no gear shift and then limits revs to the car’s maximum continuous running rpm of 6,500.

“Turbo engines with flat torque curves can often feel like they run out of steam at the top-end, but we wanted to reward drivers who took Focus RS to the red line,” states Urwin. “We’re really proud of the result – strong mid-range transient response and a free revving top-end.”

Straight Torque

However, Urwin believes that the power is unlikely to be the first thing drivers will notice, as to get to that redline they will have travelled along Focus RS’ 440Nm torque curve.

Offering more torque than any Ford RS production car before it, Focus RS’ torque curve has a steady state peak beginning at 2,300 rpm and running to 4,500 rpm, meaning torque can be appreciated in any gear and at most road speeds. The 440Nm peak torque is a 38 per cent increase over Focus ST.

Says Urwin: “Matching low-end responsiveness with a larger turbo and a peak of 440Nm is a real achievement. That’s a figure you would only have seen in so-called ‘supercars’ just a few years ago. It gives Focus RS a gutsy, strong pull at the lower end of the rev range – great for those wanting a powerful performance feel but also great for more relaxed everyday driving.”

Bespoke Transmission

That combination of performance ability and cruising capacity is made practical by a specially-developed, six-speed Ford RS transmission. It shares its gear ratios with the Focus ST gearbox on which it is based, with minor modifications to bearings and clutch housing and a revised, stronger differential.

Overall, gearing is one per cent longer than ST due to the larger rolling circumference of Focus RS’ specially developed tyres – further evidence of the team’s attention to every detail.

This allows gearing long enough for Focus RS to reach the all-important 100 km/h barrier in second gear.

Differential Difference

Putting the torque on the road is aided by a Quaife helical limited slip differential. The Quaife differential was first developed for the original, five-speed Focus RS in 2002, but revised and improved by Ford Team RS for the new, six-speed Focus RS. Today, it features a sixth planet gear and has been revised for increased strength and a more subtle intervention and torque transfer.

Computer-aided engineering drove the design of the differential, identifying the potential areas for increased strength. This was aided by measuring rig work and whole vehicle development, with particular attention to refining performance plots for the differential’s torque bias function, to maximise dynamic performance.

Concludes Urwin: “We have tuned the differential for a progressive torque transfer. Our work was focused on creating an optimum drive for both road and track, in the dry and the wet. It was in finding this balance that our tuning efforts were directed.”

2009 Ford Focus RS

Cooling RS

Creating a high-performance version of the Duratec 2.5-litre with this level of power also required significant attention to its cooling ability. The cooling strategy was two-fold:

- create a cooling pack that met the high performance requirements of Focus RS and;

- match this to a comprehensive aero pack that delivered the required volume of cooling air to the system.

Explains Urwin: “Around 80 per cent of the external cooling for Focus RS comes through the car’s lower front grille aperture and its precise size, shape and mesh density were a critical part of our work with the Aerodynamics team.”

The lower front aperture is approximately 30 per cent larger than that of Focus ST and none of the precious cooling air it collects is allowed to escape, thanks to carefully designed ducting.

This ‘upstream’ ducting focuses airflow channelled into the car’s main trapezoidal aperture by the front air splitter and front bumper form, with the exact shape dictated by many hours of research, including Computational Fluid Dynamics (CFD) and wind tunnel work.

Outboard trapezoids either side of the main intake are blanked off, but positioned to give the option of converting to additional cooling systems for serious track use.

A new, 25 per cent larger capacity radiator keeps engine coolant and engine oil temperatures under control, even in the most committed performance driving, in combination with a larger, 14-plate, engine-mounted, water-cooled oil cooler.

The final part of the engine cooling picture is Focus RS’ signature bonnet louvers, which Urwin identifies as having a particular benefit: “The louvers help with idle cooling, especially after high speed running, such as on a circuit, so were an important addition to Focus RS. They’re there for a reason.”

Testing of the cooling pack took place around the world, to find the broad range of required conditions, including Arizona, Southern Italy, the Austrian Alps and a variety of European race circuits.

“CFD helped us in the early stages of cooling development, but there’s no substitute for real-world testing. We spent significant time testing physical prototypes, in wind tunnels and variety of real-world climate extremes to perfect this work,” explains Urwin.

RS Breathing

The new intake system for Focus RS includes a new body-mounted airbox with a low-loss, cylindrical filter, revised turbo ducting, a modified hot charge duct, high-efficiency intercooler and new cold charge duct. The airbox also has a unique, double intake entry system to reduce induction losses further.

Intercooling is critical in high-performance engines and the Focus RS intercooler system is new, larger and specially developed for the car. It is capable of reducing air temperatures from 160 degrees Celsius at the compressor, to a maximum of 60 degrees Celsius at the intercooler outlet, in ambient temperatures of up to 38 degrees Celsius.

RS Exhaust

The sports exhaust system is also unique to Focus RS. Focus RS uses a one-brick catalyst to enhance flow and reduce exhaust back-pressure, whilst meeting current exhaust emissions requirements.

The design of the turbo and manifold allows Focus RS to use ST’s exhaust geometry, downpipe and flex, with revised hangers to accommodate the car’s 20mm lower subframe.

The exhaust system also features a modified mid-section, with a revised, 4.2-litre mid-muffler, fitted around Focus RS’ larger, 62-litre fuel tank (up from 55 litres in Focus ST). At the rear, a modified muffler uses two larger, 100mm-diameter, ‘trumpet’ tailpipes to further reduce pressure losses.

The entire system has been tuned to provide a sporty sound. Team RS engineers knew well that, for Focus RS customers, how the exhaust system sounds is as important as how it looks or performs. Every Focus RS customer wants their car to sound ‘right’ and creating an induction and exhaust sound to fit the image and character of Focus RS was another critical aspect of its powertrain development.

Focus RS employs a ‘sound symposer’ system, to amplify selected engine frequencies and convey pleasing engine sounds into the cabin, contributing to that all-important RS performance environment. As in all aspects of the engine, the symposer system has been adapted and tuned to fit the character of the vehicle, giving a raw, motorsport edge not present on Focus ST.

Urwin’s Powertrain team also created detailed performance characteristics to delight enthusiasts, such as a spark retard that encourages the pop and crackle in the exhaust on throttle lift. Focus RS also has a distinctive, more aggressive idle tempo and engine note, to reinforce performance feel.

All these details were tuned to meet strict EU production car noise regulations and Focus RS’ own targets for fuel economy and durability.

Explains Urwin: “We’ve gone as far as we can for a production car. In all of our engine development, we have to stay within EU drive-by noise limits, provide good overall fuel economy for the class and meet exacting durability and emissions standards – yet still create a high-performance engine with an attractive, sporty induction and exhaust noise. Achieving that is all about balance and a tireless attention to detail.”

Focus RS Performance

Creating the power of a true Ford RS is one thing; managing that power into accessible yet exhilarating performance and assured traction is another. This challenge was met by Ford’s renowned vehicle dynamics experts.

Under the guidance of Chief Programme Engineer, John Wheeler, the Dynamics team was led by Chief Engineer, Dirk Densing, whose relaxed demeanour belies his passion and pedigree in performance cars and motorsport.

This team has achieved a car capable of 0-100km/h (0-62 mph) in 5.9 seconds and a top speed of 263 km/h (163 mph).

Wheeler and Densing were determined to create a dynamic mechanical set-up that would provide a pure driving experience, rather than manage power with constant electronic interference or truncation systems.

The most obvious change is the car’s wider track, but the team completed their solution with a suspension technology that was under development at Ford’s Research & Advanced Engineering centre (R&AE) in Aachen, Germany. Called ‘RevoKnuckle’, this innovation was identified early on as offering significant benefit to a new front-wheel-drive RS.

The combination of wider track and RevoKnuckle front suspension is the reason Ford has been able to do what was thought impossible previously: develop a 305PS (300 bhp), front-wheel-drive car that is not only driveable every day, but faster in many situations than all-wheel-drive performance cars.

Exhaustive testing and refining in the hands of Team RS’ dedicated vehicle dynamics expert, David Put, has also created a set-up for Focus RS that forgives the bumps of every day roads, yet rewards on-track commitment.

“It sounds simple, but is a genuine challenge: make a potent performance machine as accessible and useable as any other Focus; able to transform instantly from everyday transport to track-day ‘supercar’,” explains Wheeler. “It’s a combination of innovative technology and class-leading dynamics, finely honed through David’s expertise and commitment that made this possible.”

Torque Talk

The greatest engineering challenge was in managing the impact of the car’s 440Nm torque. Torque steer – the impact of torque on steering in front-wheel-drive vehicles – is one of the key challenges in suspension development of front-wheel-drive cars.

In the real world, torque steer is most often experienced when hard acceleration, cornering or uneven surfaces are combined and its effects are apparent to the driver as a sudden or momentary disturbance on the steering wheel. This is not ‘performance feel’, but a transient ‘error state’ which detracts from steering precision and performance.

Wheeler explains the phenomenon: “Torque steer is experienced when an unequal traction forces exists between the left and right front driven wheels. On a good flat surface, driving straight ahead, the left and right driven wheels have equal driving torque and everything is balanced.

“When left and right torque is unequal then the trouble starts. In the design of front-wheel-drive suspension, two main aspects have to be considered to minimise torque steer: keeping the centre of the outer CV joint on the steering axis line, and minimising the offset from the wheel centre to the steering axis. This is most important in performance cars, where wider wheels create a greater offset to begin with,” he continues.

In the physics behind this phenomenon, traction forces at the tyre’s contact area with the road are translated in two ways: one force ‘couple’ transfers harmlessly through the driveshafts, but a second force component acts at the wheel centre. This element creates a turning force about the steering axis. The larger the offset between the wheel centre and the steering axis, the larger the turning torque.

In the design of the suspension geometry, therefore, the first priority is to keep the offset from the wheel centre to steering axis as small as possible.

Even this is not an exact science since, with wide tyres on uneven road, the tyre’s contact area with the road can move from the middle to the inside or outside of the tyre.

These unbalanced forces can be exacerbated further by a limited slip differential, as some have a very unforgiving characteristic of locking and applying transfer torque too rapidly.

Considering wide tyres, a wide track and wheel offset and limited slip differential are all present in the front-wheel-drive Focus RS, these areas were the first to be considered by the Dynamics team.

Tuned RevoKnuckle Technology

RevoKnuckle technology was originally conceived as the trend developed for high torque diesel engines to move from large, often all-wheel-drive vehicles into smaller, front-wheel-drive cars. The Ford RevoKnuckle approach is unique in its design and installation and has been developed and patented exclusively by Ford Research & Advanced Engineering (R&AE) and Team RS.

Ford RevoKnuckle is the product of six years’ work, beginning in 2001 and led throughout by project engineer, Marc Simon. While Focus RS is R&AE’s first performance car application, Simon’s team was able to bring significant relevant experience to the project: in 2005, Simon and several other R&AE specialists were seconded to Ford’s World Rally team, developing the suspension layout and kinematics of the then-new Focus World Rally Car.

This gave them a sound understanding of the requirements for Ford RevoKnuckle in a high-performance road car, in both its functionality and durability. “There’s a direct relationship between what we were doing in WRC and our work on Focus RS,” Simon states.

RevoKnuckle Structure

The performance demands of Focus RS mean it is the only model in the Focus range not to carry the traditional ‘MacPherson strut’ arrangement.

Regular suspension knuckles are a one-piece design; RevoKnuckle has instead two separate pieces – one part fixed to the strut; one part that rotates with the steering line of the car.

In place of the regular, inverted ‘L’-shaped lower suspension mount, RevoKnuckle features a ‘C’-shaped mount, connected to both the wheel hub, via two arms and to the strut, which is attached at its top.

This approach afforded engineers far greater flexibility to set the car’s suspension geometry to minimise torque steer, particularly by reducing the critical distance – known as the ‘king-pin offset’ – between the wheel centre and the steering axis line.

The structure of RevoKnuckle provides a layout where the familiar spring/ damper strut and lower wishbone dictate the basic wheel control and geometry, but provides a separated king-pin axis, more often associated with a double wishbone design. This provides more freedom in suspension set-up – such as application of camber, castor and trail – without the need for an expensive suspension re-design. Most significantly, it also creates a king-pin offset less than half that of a conventional McPherson with wide track.

“RevoKnuckle allows the strut and lower wishbone to dictate the basic wheel control and geometry, but provides a separate king-pin axis – in effect, moving the turning line of the wheel closer the wheel centre,” explains Densing.

Ford RevoKnuckle Patented

Ford succeeded in combining the new RevoKnuckle with the proven Focus front suspension layout that is normally equipped with McPherson struts. The work to create this unique combination is now protected by a Ford patent.

RevoKnuckle has been patented by Ford for a key aspect of its design: the additional connection between RevoKnuckle and the front anti-roll bar, critical for its high resistance to rotation.

“RevoKnuckle is a straightforward piece of suspension design, in an innovative application that makes it absolutely right for a high-performance car. The explanation may be a little scientific – the result is genuinely dynamic,” says Simon.

Innovative Mechanical Approach

In Focus RS, RevoKnuckle has been developed to work alongside the differential in enhancing traction and drive in a range of situations. Focus RS’ Quaife epicyclical design relies heavily on friction of the gear surfaces which builds with differential speed, and has been tuned finely to avoid snatch and rapid torque changes.

Such a mechanical approach was very deliberately chosen over other available solutions, such as electronic torque truncation, or Electric Power Assist Steering algorithms to ‘mask’ torque steer effect by adding ‘counter-steering’ force into the steering system.

“We weren’t interested in masking torque steer or reducing performance to the point where it wasn’t an issue. We have managed to reduce torque steer to a minimum, yet keep all the performance an RS should have,” concludes Simon.

According to John Wheeler, the importance of RevoKnuckle to Focus RS cannot be underestimated:

“All-wheel-drive or rear-wheel-drive have long been default options for managing torque in a high-performance vehicle. We used AWD on RS models in the 80s and 90s, but it creates significant compromises in weight, fuel economy and the cost/ performance balance. Through combined efforts of our Research and Dynamics teams, we have created a solution that simply redefines what is possible with front-wheel-drive,” he says.

Summarising the benefits of RevoKnuckle, Densing says: “RevoKnuckle gives the adjustability of a race-car style, double wishbone suspension, in a cost-effective McPherson architecture.”

Stopping Power

With such performance capability on tap, it’s no surprise to find Focus RS offers a vice-like braking performance. Large 336mm x 30mm, ventilated front discs are gripped by stiffer, single 60mm piston calipers, supported by 302mm x 11mm rear discs. Focus RS also boasts unique high-friction brake material and a tandem brake booster, all combining to generate up to 1.2 g under braking and give Focus RS a stopping distance of just 34.8 metres (114 feet) from 100km/h (62mph).

Anti-lock braking with Electronic Brake Force Distribution (EBD) is standard, as is Ford’s Electronic Stability Programme (ESP), here tuned specifically for the car, to allow a high level of sporty driving before intervening.

“In some cars, ESP limits fun for the enthusiast, because it can be used to disguise chassis weaknesses,” explains Densing. “In Focus RS, the ESP system is tuned for later and shorter interventions, so you don’t feel engine intervention and only occasional brake intervention, even on race circuits, or in rain.”

The ESP system can be deactivated for circuit driving. However, this may not always be necessary, as Densing highlights.

“Because it’s so precisely tuned, our engineers have lapped the Nuerburgring just as quickly with ESP on, as with it off,” he states.

Stable High-Performance Set-Up

By employing RevoKnuckle, the Focus RS Dynamics team was able to retain Focus’ suspension layout, including ‘Control Blade’ independent rear suspension set-up for stability and controllability, albeit tuned and lowered by 20 mm for a performance driving character.

“Ford Focus’ fundamental dynamic character makes an excellent base for a high performance car – it’s agile, responsive and stable. It required only subtle changes for Focus RS,” explains Densing.

At each corner, Focus RS is set up with stiffer springs and higher spring rates, with rear spring rates increased 40 per cent, versus Focus ST. These are matched to thicker and longer, 24mm anti-roll bars, aiding stability and mechanical grip.

Front and rear track width has been increased by 40mm versus Focus ST, with the resulting wider wheel offset and increased overall vehicle footprint sharpening handling and improving stability.

At the same time, the front subframe has been lowered 20mm, giving a low roll centre height.

The highly acclaimed Focus independent rear suspension has been refined to reflect the RS’ high performance intent, particularly in managing higher lateral acceleration. This is achieved through a rigid, cast suspension knuckle and larger rear wheel bearings, the combination of which improves stiffness significantly, creating the low rear suspension camber compliance critical to a responsive high-performance car.

The rear anti-roll bar has also been modified to control immediate roll, heightening vehicle stability and maintaining a fun-to-drive character.

The Dynamics team studied and developed further the ‘elastokinematics’ of the Focus rear suspension, generating a more direct build-up of cornering forces through reduced lateral compliance, for a more immediate and linear steering response.

Finally, David Put himself worked closely with tyre manufacturer, Continental, to develop a specific compound tyre for Focus RS. The car’s 19-inch alloy wheels are thus wrapped in 235/35/R19 bespoke Continental tyres, giving superior road contact and huge lateral grip.

“Behind the wheel, all this translates into a direct response and a high level of cornering controllability, without sudden surprises for the driver. On a circuit, the driver can feel exactly what Focus RS is doing and predict it safely,” says Densing.

Dynamics Tuned for Precision

Ford’s renowned driving dynamics DNA comprises four pillars: stability, precision, comfort and agility and each Ford car carries a different balance of these attributes.

In outright racing cars, comfort is the least important. Yet, while Focus RS drivers will accept a little less comfort for greater high-speed stability, agility and directional precision, engineers needed to maintain the sophisticated Focus ride and handling as far as possible, as the car must be equally competent as everyday transport.

“Focus RS has a different character from Focus ST, with a more overt sporting nature. RS is intended to meet the needs of the serious performance driver when this is demanded, yet still provide a fully acceptable and rewarding vehicle for daily driving. In dynamics terms, that’s a fine balance between raw, race circuit performance and the controlled precision required for on-road driving,” says Wheeler.

With stability and controllability in check thanks to the suspension set-up and RevoKnuckle, dynamics engineers moved on to concentrate on agility and precision.

In Focus, this is characterised by a fundamental turn-in tendency that tucks in the car’s nose on throttle lift. This is more pronounced in Focus RS, by a more acute castor angle to the front wheels, for a keener dynamic response to throttle adjustments.

Focus’ Electro-Hydraulic Power Assist Steering (EHPAS) has also been tuned with a lower ratio (13.2:1, versus 14.7 for Focus ST), providing sharper responses and requiring less steering effort in cornering, with just 2.32 turns, lock-to-lock.

Ensuring the car’s weight did not rise too far was critical to handling as well as ensuring good performance feel. Thanks to RevoKnuckle, which negated the need for all-wheel-drive, and the close attention paid to detail throughout its development, Focus RS weighs in at 1,467 kilograms. This is 75 kilograms heavier than a three-door Focus ST, an increase spoken for by the larger wheels, tyres and brakes, limited slip differential and aerodynamic and cooling aids.

“It doesn’t just feel faster; it’s also sharper and more responsive,” explains Put. “In cornering, you will notice how the improved braking performance, higher lateral mechanical grip and sharper steering responses allow you to carry more speed into and through the corner apex. The car also carries a flatter attitude in a corner and has a more rapid load transfer. It reacts faster to directional changes on twisty roads or race tracks and you can adjust its line on the throttle, so you can get back on the power quickly out of the turn.”

Aerodynamics

Aerodynamics also played a part in the Dynamics team’s work. Says Densing: “Aero is very important to any car, but usually concentrated on not creating lift front to rear. With its sophisticated aero package, Focus RS generates genuine downforce at circuit speeds and we’ve covered thousands of kilometres refining computer simulations to find the right balance of downforce without too much drag.”

The target for high speed stability of a performance car is to position the aerodynamic centre of pressure at a controlled point behind the centre of gravity.

In Focus RS, the starting point was the standard Focus shape, crafted to generate moderate front end and rear end lift at higher speeds. The challenge was to transform this lift into downforce and bring the aerodynamic centre of pressure forward, without undue sacrifice to the drag coefficient and top speed.

Extensive wind-tunnel testing was conducted to refine aerodynamic performance, with a target of delivering about 40 points of downforce at the front and 10 points at the rear.

The resulting aerodynamic elements for Focus RS achieve these targets, creating 26 per cent more downforce than Focus ST, yet with a drag co-efficient (Cd) of 0.38.

The result of all this effort is a car that is not just fast in a straight line. It is the fastest ever car around the infamous handling circuit at Ford of Europe’s Lommel Proving Ground in Belgium – known to the team as ‘Route 7’ – beating even the Ford GT and cementing its dynamic credentials.

In addition, Focus RS has completed over 400 laps (over 8,000km) of Germany’s fearsome Nuerburgring Nordschleife during its circuit performance development.

The purpose of all this work was to ensure Focus RS continues and enhances Focus’ reputation as a driver’s car and stays true to its core philosophy of generating pure driving enjoyment by flattering the novice driver, while rewarding the expert.

Focus RS Style

Focus RS exudes its intent of being the ultimate Ford performance car of its generation and strikes a lasting impression with performance car enthusiasts.

“Kinetic design visualizes the dynamic qualities of a vehicle, transmitting a feeling of driving excitement, but true to the character of each vehicle,” explains Ford of Europe’s Executive Director of Design, Martin Smith. “In design terms, every member of the Ford of Europe family has its own personality. Mondeo is the most premium; Fiesta the most stylish; Ka the friendliest – RS is quite simply the meanest!”

In design as in concept, Focus RS is inspired by Ford’s World Rally Championship success and this is most obvious in its large, gloss-black front trapezoidal air intake, creating an immediate visual link to the Focus World Rally Car – design for the road, true to motor sport principles.

Heightened aerodynamic and cooling needs meant Focus RS required a specific design approach that integrated these requirements and differentiated it from mainstream Focus aerodynamic elements.

Rather than settle for grafting performance detailing onto a standard body shape, designers have revised almost every body panel on Focus RS to create its bespoke shape.

The result is cohesive and dramatic; new front and rear bumpers and integrated side rocker mouldings give Focus RS a lowered, meaner appearance, while a revised bodyside with wider wheel arches, rocker mouldings and vents give the vehicle a more purposeful stance. These are topped by possibly the most dramatic of Focus RS exterior features, the imposing rear spoiler, inspired directly by the Focus World Rally Car.

Necessary aerodynamic elements are contrasted with the body colour of the car by a gloss-black finish and together they provide some of the vehicle’s more distinctive styling cues.

Smaller, secondary cues provide visual differentiation to mainstream Focus models:

- Twin panels of louvres on the bonnet and small vents underneath the headlamps reinforce the car’s performance intent and augment the recognised Ford Focus shape;

- RS badges throughout the car reinforce the car’s RS pedigree: three dimensional RS badges are present on each front wing vent, the upper radiator aperture, tailgate and embossed on each wheel;

- 19-inch, 15-spoke polished alloy wheels echo the look of their World Rally equivalents.

“Imagine a Focus WRC roaring through a stage in Monte Carlo – you know immediately what it is from front graphics, flared arches, and distinctive livery. Our intention is to make Focus RS equally and immediately recognisable.” states Smith.

Performance Design, Aerodynamic Purpose

Focus RS’ major design features are all functional, as well as styled to create a lasting impression, with each doing an important job in managing the airflow over and into the car.

“A high performance car like Focus RS has very different and much more sophisticated cooling requirements than a standard car, so design works hand-in-hand with aerodynamics,” explains Chief Exterior Designer, Stefan Lamm. “RS is also lower and wider, not only to give the right impression, but also to ensure more downforce and less uplift than Focus ST. This is fundamental for responsive high-speed handling on circuits.”

From the outset, Team RS worked with Ford’s design and aerodynamics specialists to ensure performance style met performance requirements. The prominent front air splitter, twin-blade rear spoiler and rear venturi all underwent significant aerodynamic testing to achieve the right cooling and aerodynamic targets.

For example, while echoing the standard Ford trapezoidal silhouette, the front splitter’s intake area and structural cross bars have been precision honed to allow the required volume of air into the car’s cooling system.

The gloss-black front splitter also has a role in controlling exterior airflow, working with the rear venturi in managing air movement under the car, to help develop the required downforce for circuit use. The venturi then channels the air bisected by the front splitter, directing it out from underneath the car and past the rear bumper.

Significant aerodynamic analysis went into the design and construction of the rear venturi tunnel and rear spoiler. Here, Ford’s World Rally expertise came into its own to determine the precise height, ramp angle and position of the car’s twin-blade spoiler, for maximum aerodynamic efficiency.

Explains Lamm: “Customers would expect an RS to have a rear spoiler, but on Focus RS this has been designed very precisely. A large front splitter creates a large aerodynamic force at the front and could make the rear light and nervous in high speed handling. So, the rear spoiler and venturi have been developed painstakingly to balance the downforce between front and rear. In a true high-performance car like Focus RS, this ability to collect, extract and manage airflow efficiently is critical to its design.”

Distinctive Colour Options

To reinforce the bold, new, motorsport-inspired design, designers knew colour was as vital ingredient of the overall Focus RS package.

The positive reception given to the signature ‘Electric Orange’ colour that became a highlight of the Focus ST launch encouraged the Design team to develop an equally exciting and unique ‘hero’ colour for the sportier Focus RS.

Their inspiration for the vibrant, new ‘Ultimate Green’ came from the livery of Focus World Rally Cars. The colour reflects the green signature colour of Ford’s global partner and World Rally Championship sponsor, BP, and also stands as a modern interpretation of the 1970s Ford Escort RS Le Mans Green colour.

“Focus RS is a car designed to grab your attention and the choice and use of colour is vital,” says Stefan Lamm. “Colour can define a brand, as we saw with Focus ST and in this case we wanted something even more energetic and dazzling. Green is a critical colour that has to have the shade tuned perfectly and ‘Ultimate Green’ captures and communicates the spirit and energy of Focus RS.”

Focus RS will also be available in the classic RS choice of Frozen White or Ford Performance Blue, the colour of the original Focus RS.

In each case, body colour is used not just in contrast to the gloss-black exterior elements, but also extends to the car’s interior.

High-Performance Interior

On the inside, Focus RS boasts a unique and appropriately performance-oriented interior, designed to appeal to customer tastes and balance genuine sports performance with a strong sense of style and quality.

The cabin is dominated by bespoke Recaro high-performance sports seats, specially designed and trimmed in an authentic motorsport microfibre, a tactile material that also provides the grip and support necessary when driving enthusiastically. Each is colour-matched to the exterior, with ebony leather accents and ‘RS’ and ‘Recaro’ logos stitched into each backrest. Alternatively, optional Ebony black, partial-leather seats will be available with all exterior colours.

Elsewhere, colour builds on the sporty interior theme introduced in Focus ST, with even bolder performance styling, more use of colour matching to the exterior and wide use of metallised and carbon accents.

Rear seats are sculpted, featuring the same detailing and high side bolsters as the front sports seats, making Focus RS a genuine four-seat vehicle.

The centre console is finished in a stylish, carbon-look trim and metallised highlights include air vents, door grab handles, switchgear and gearshift surround and unique RS-branded scuff plates on the door sills. These highlights contrast with a black-trimmed roof lining, emphasising the sporty, cockpit feel.

The driver is also reminded this is no ordinary Focus at every touch, with each interaction refined to match Focus RS’ sporty character.

At the centre of this experience is a chunky, three-spoke steering wheel with RS signature and shorter-throw gear lever, with a slick, precise action and a six-speed gear shift graphic in RS blue. The performance driving environment is completed by aluminium foot pedals and three additional gauges, including turbo pressure, sitting atop the centre console and angled toward the driver.

Green or blue interior options are available, matched to the Ultimate Green or Performance Blue exterior options. Frozen White interior colour is blue.

Explains Martin Smith: “Just as the exterior must describe performance potential, so the interior must create a genuine sporting environment, in looks and performance. For example, the use of microfibre is tactile and grips occupants, while a branded Recaro seat communicates immediately an authentic motorsport capability.”

Contemporary ‘RS’

Inside and out, Focus RS has been styled for a modern generation of performance car enthusiasts, reflecting modern customer tastes.

For the first time in its heritage, even the 38-year-old RS badge has been restyled subtly, as a more modern interpretation for the new car. It features a bolder, more solid identity and a more subtle chrome surround.

“Focus RS is kinetic design to the max, an all-modern, ultimate performance Focus with attitude. To me, the RS maximises the potential of Focus and defines a new generation of the iconic RS brand,” concludes Smith.

Focus RS Practicality

Focus RS is not just a new high-performance car, it also marks the pinnacle of the Focus road car range. While it is guaranteed to thrill and excite customers with its power and performance, it must be just as impressive in everyday use.

Inconspicuous Consumption

All the work carried out in fine-tuning the design and specification of the Focus RS in terms of aerodynamics, powertrain details and chassis set-up not only assisted the car’s precise dynamic response and performance, but also the everyday consideration of its fuel economy and emissions.

For a 305PS high-performance car, Focus RS is remarkably efficient, with European Driving Cycle combined fuel economy of 9.4 litres per 100km (30.0 miles per gallon) and an average CO2 rating of 225 grams per kilometre1.

Combined with a larger, 62-litre fuel tank (up from 55 litres in other Focus models), this gives Focus RS a healthy driving range.

“It was important for us to develop a vehicle which combines high performance with fuel economy. In the 300+ PS category, Focus RS is amongst the leaders for fuel economy,” comments Wheeler.

Sound, Not Noise

Within Ford of Europe, noise, vibration and harshness (NVH) work is known as Sound Quality and Vibration (SQ&V), and is a vital element in keeping Focus RS’ sensory connection between car and driver.

Unwanted noise and vibrations have been minimised, using new, stronger engine mounts to absorb engine vibrations and a new roll restrictor bracket, which improves dynamic engine control by 20 per cent. The interior NVH package from Focus ST has also been used to prevent unwanted wind and road noise entering the cabin.

Distinctive, sporting sound qualities have been tuned in to the high throttle opening and higher engine rpm ranges, to reward the enthusiastic driver. The sound symposer delivers the powerful intake sound into the cabin, while the exhaust system features a rough and sonorous sound unique to RS.

States Wheeler: “In a performance car, the right sound is important. A sound package that is harmonious with the vehicle’s performance and provides a positive driving experience is as important as the suppressing of unwanted noise.”

Safety and Structure

Under its stylish, performance exterior, Focus RS continues Focus’ excellence in active and passive safety.

The Focus RS safety package includes standard ABS, Electronic Brakeforce Distribution, ESP and a rigid passenger safety cell. Among the interior safety systems are driver and passenger front airbags, side curtain airbags and pyrotechnic belt pre-tensioners protecting front and rear occupants.

In November 2004, Focus was the first and only vehicle to be awarded a 100 per cent occupant safety rating by EuroNCAP, for both offset frontal and side impact. It also achieved a 100 per cent test score for child dynamic injury protection for 1? and 3-year-old child crash test dummies.

Retaining Focus Reliability

All through Focus RS’ development, durability has been as important as any other factor and much attention to detail has ensured it will continue Focus’ excellent reputation for reliability, despite all its high-performance modifications.

This was especially true for the bespoke suspension design. For all its complexity, creating the function and set-up of Ford RevoKnuckle was just part of the challenge for engineers in Ford Team RS, Vehicle Dynamics and R&AE. Bringing such an innovative development into volume production and meeting Ford’s exacting durability standards was equally important.

Explains Wheeler: “Targets for durability are higher for Focus RS than mainstream vehicles, because of its likely use as a track car. It will be driven harder and expected to perform to higher levels than other Focus models.”

One of the early decisions in meeting durability targets was to move from an aluminium steering knuckle to a forged part, with the static knuckle in cast iron. This makes for a much stronger, durable component, designed for serious track use, yet adds only three kilogrammes to the overall weight of the car. RevoKnuckle has also been developed with due consideration for easy service and maintenance, making it simple to maintain and allowing Focus RS to be covered by the standard Ford of Europe warranty.

Powertrain modifications were also made with attention to durability. For example, cylinder bores on the engine have been metal sprayed on the inside, to protect against cylinder cracking under the higher engine pressures generated by the larger turbo.

Approximately 10,000 hours of vehicle testing and development and almost 1,000 rig and vehicle-based tests went into assuring durability on Focus RS.

Wheeler explains: “Our focus was on giving the customer a fully engineered car that delivers high performance without the traditional compromises of performance tuning. We’ve worked extensively to make sure Focus RS is as durable as every other Focus, and introduced additional test programmes to ensure durability under high speed and race track conditions.”

Straightforward Production

Production of Focus RS is also straightforward, with the car being assembled on Ford of Europe’s principal Focus production line in Saarlouis, Germany. The front suspension and RevoKnuckle is accommodated in a sub-assembly before final assembly, ensuring the only line modifications required were to accommodate Focus RS’ wider track.

“This car is the perfect way to celebrate our success with RS and with Focus, on both road and rally. It’s the fastest European Ford production car ever, the most powerful Ford RS and probably the most powerful front-wheel-drive car on sale today. Any way you look at it, it’s something special,” concludes Wheeler.

RS Heritage

In 1968, man had not yet landed on the moon, Concorde had not yet flown and the newly-created Ford of Europe had just delivered its first car, the Ford Escort.

Against this backdrop, the Ford RS marque was born quietly, in Germany. The 15M RS (P6), 17M RS and 20M RS (P7), all began production in March 1968 and were the first ever Ford vehicles to carry the RS name, though none carried the badge.

It was not until two years later in 1970 that Ford – inspired by early success in “Rallye Sport” – introduced its first European RS performance car, the Escort RS 1600. The RS identity has been an important part of Ford’s sporting image ever since.

In the 40 years since its first appearance, the RS marque has been applied to just 22 of the most special individual Ford road cars, each and every one offering stand-out performance and value for money.

RS Fords have been built in many different forms. They have been front-engined or mid-engined; all-wheel-drive, rear-wheel-drive or front-wheel-drive; and with four-cylinder or six-cylinder, normally-aspirated or turbocharged engines.

Most have employed wind-tunnel testing to evolve aerodynamic features, from Sierra and Escort RS Cosworths right up to new Focus RS.

Yet, all have pushed out the boundaries of technology and virtually all have been successful in motorsport. As a result, each has held a unique place in its market and shared in a proud sporting pedigree.

The original Ford RS – the Escort RS1600 – was the first Ford to use a 16-valve twin-overhead-camshaft engine, and the first to be assembled in the new Advanced Vehicle Operation factory at Aveley, in Essex, UK.

Like many subsequent RS models, the RS1600 found worldwide success in races and rallies, such as the 1972 East African Safari rally and the 1974 European Touring Car Championship.

Elsewhere, Ford Capri RS2600 and RS3100 models were not only high-powered flagship versions of Ford’s best-selling coupe range, but also won scores of races, including the 1971 and 1972 European Touring car Championships.

In the late 1970s, the quad-headlamp RS2000 became the best-selling RS model to date. Escort RS1800s won the 1979 World Rally Championship for Makes, and provided power for both Bjorn Waldegard (1979) and Ari Vatanen (1981) to win their respective Drivers’ titles.

In the 1980s, the first front-wheel-drive Ford RS, the Escort 1600i, was the first to use fuel-injection and a five-speed gearbox, while the Escort RS Turbo was the first to use a turbocharged engine and a limited-slip differential.

The mid-engined RS200, of which only 200 were produced between 1984 and 1986, was intended for Group B rallying and featured a race-bred aluminium honeycomb, steel chassis, carbon and Kevlar-fibre upper structure, a turbocharged Cosworth BDT engine and all-wheel-drive. Strikingly styled by Ghia, the RS200 was the most exclusive and most expensive Ford RS ever sold. In the years since, it has also been a familiar presence in the sport of rallycross.

In the late 1980s, the Cosworth YB-powered, 150mph Sierra RS Cosworth range became successful as fast, value-for-money road cars, while the RS500 derivatives were so dominant in motorsport that entire Championships had to be re-cast to make sure they did not win every race.

Even so, the 500bhp RS500 race cars won the 1987 World Touring Car Championship and the 1988 European Touring Car Championship.

The following decade saw the Escort RS Cosworth return Ford to the top of rally standings, including victory in the 1994 Monte Carlo Rally – inspiring the birth of the 1990s Escort RS Cosworth road cars. It also led onto 1997-1998 Escort World Rally Car, which brought the Escort rallying pedigree to a victorious close.

Two high performance versions of the front-wheel-drive Fiesta were also created in this period – the RS Turbo and RS1800, the latter with the award-winning Zetec 16-valve, twin-cam engine. Later, there were distinctive front-wheel-drive and four-wheel-drive Escort RS2000 models.

Then came Ford of Europe’s design and engineering revolution that created the Ford Focus, in 1998. The RS name made a welcome return in 2002 on the first-generation, 215PS Focus RS, which continued the Ford RS pedigree, using a turbocharged Duratec 2.0-litre engine and limited slip differential to create a ‘World Rally car for the road’ experience.

Its strictly limited-edition, 4,501 production run sold out rapidly, proving the enduring demand for high-performance Fords across Europe – a demand which was met in 2009 by the launch of the all-new, 305 PS Ford Focus RS.

Chronology of Ford of Europe RS vehicles:

| Model | Launched |

| Escort RS1600 | 1970 |

| Capri RS2600 | 1970 |

| Escort RS2000 | 1973 |

| Capri RS3100 | 1973 |

| Escort RS1800 | 1975 |

| Escort RS Mexico | 1976 |

| Escort RS2000 Mk II | 1976 |

| Escort RS1600i | 1981 |

| Escort RS Turbo | 1984 |

| RS200 | 1985 |

| Sierra RS Cosworth | 1985 |

| Escort RS Turbo | 1986 |

| Sierra RS500 Cosworth | 1987 |

| Sierra RS Cosworth (saloon) | 1988 |

| Sierra RS Cosworth 4x4 | 1990 |

| Fiesta RS Turbo | 1990 |

| Escort RS2000 | 1991 |

| Escort RS Cosworth | 1992 |

| Fiesta RS1800 | 1992 |

| Escort RS2000 4x4 | 1994 |

| Focus RS | 2002 |

| Focus RS | 2009 |

TECHNICAL SPECIFICATIONS

| ENGINE DATA | ||

| Engine Type | 2.5L 20 V DOHC RS | |

| Displacement (cc) | 2522 | |

| Bore (mm) | 83.0 | |

| Stroke (mm) | 93.2 | |

| Fuel type, grade | Unleaded petrol, 98 or 95 (RON) | |

| Max power ISO PS (kW)At engine speed (rpm) | 305 PS (224kW)6500 | |

| Max torque (ISO Nm)At engine speed (rpm) | 440 Nm2300 - 4500 | |

| Compression ratio | 8.5:1 | |

| Cylinders | 5, in-line | |

| Cylinder head | Gravity die cast aluminium alloy with sintered valve guides and seats | |

| Cylinder block | High pressure die-cast aluminium alloy with bed plate, metal-sprayed bores | |

| Crankshaft | Forged Steel with 50 mm-diameter crankpins, fully balanced with ten counterweights, six 65mm-diameter main bearings and damped front pulley, overall weight 21,5 kg. Lead free bearing shells | |

| Valves per cylinder | 4 | |

| Valve gear | DOHC | |

| Included angle between valves | 58 degrees | |

| Valve sizes (mm) | Intake: 31.0Exhaust: 27.0 | |

| Turbocharger | Borg -Warner K16 integrated turbo system, one-piece precision-cast thin-wall iron housing | |

| Camshaft drive | Tooth belt with dynamic tensioner, Ti-VCT (Twin independent Variable Cam Timing), timing variation 50° (intake), 30° (exhaust) | |

| Pistons | Lightweight, short-skirt silicon-aluminium alloy pistonwith graphite-coated piston sleeves | |

| Connecting rods | Forged steel with fracture-split big ends, 143 mm length | |

| Max engine speed (rpm)Idle engine speed (rpm) Engine speed at max speed (rpm) | 7050 transient (3 seconds)with continuous at 6500 8006175 | |

| Engine management | Bosch ME 9.0 Motor-Management System for Injection and Ignition, EURO Stage 4 | |

| Fuel injection | Sequential electronic fuel injection (SEFI) | |

| Ignition | Electronic distributorless | |

| Emission controls | Under-floor closed-loop three-way catalytic converter with oxygen sensor | |

| Emission level | European Stage IV, with electronic on-board diagnostics (EOBD) | |

| FLUIDS | ||

| Fuel Tank (litres) | 62 | |

| Cooling liquid (litres), incl. heater | 7.1 | |

| Oil quantity, incl. filterOil Change Service Interval | 5.8Every 20,000 km / 12,500 miles Annual or every 20,000 km / 12,500 miles | |

| Transmission | ||

| Transmission type | Manual 6-speed, synchromesh on all ratios including reverse | |

| Gear ratios | ||

|

6th 5th 4th 3rd 2nd 1st Reverse Final Drive |

0.7 0.868 1.088 1.433 2.05 3.385 3.231 4.00 |

|

| Clutch type | Single dry clutch with self-adjusting lash mechanismand dual mass flywheel | |

| Clutch diameter (mm) |

240 |

|

| Differential | Mechanical, Quaife helical limited slip differential, 6 planet gears, 32-degree helix angle | |

| Suspension | ||

| Front Suspension | Independent MacPherson struts with offset coil spring over gas filled damper units and lower L-arms. Anti-roll bar (24mm).Ford RevoKnuckle with fixed mount to anti-roll bar (patented) | |

| Rear Suspension | Independent Short-Long Arm (SLA) Control Blade multi-link system mounted on reinforced sub-frame, gas-filled dampers and anti-roll bar (24mm). | |

| Steering | ||

| Type | Rack and pinion, ratio 13.2:1, lock-to-lock 2.32 | |

| Turning circle (m) | Kerb-to-kerb: 12.2 | |

| Brakes | ||

| Type | Dual-circuit, diagonally split, hydraulically operated discs front and rear. Vacuum servo-assist. Standard electronically controlled anti-lock braking system (ABS) with electronic brake force distribution (EBD). Specially-developed ESP system. | |

| Front | 336 x 30 mm ventilated discs | |

| Rear | 302 x 11 mm solid discs | |

| Body | ||

| Structure | Computer-optimised, high-efficiency, unitary-welded steel | |

| Safety elements - body | Computer optimized body structure using high strength steels and custom welded material.

|

|

| Passive safetyand restraint system features |

|

|

| Bumper system | Damage-resistant, full-depth moulded reinforced polypropylene | |

| Security system elements |

|

|

| Wheels/Tyres | ||

| Standard wheel type |

Alloy |

|

| Standard wheel size (in) |

19x8.5 |

|

| Tyres |

Continental 235/35 R 19 |

|

| Dimensions and Capacities | ||

| Exterior | ||

| Overall length (mm) |

4402 |

|

| Overall width, excl. mirrors (mm) |

1842 |

|

| Overall height (mm) |

1497 |

|

| Wheelbase (mm) |

2640 |

|

| Front tread (mm) |

1586-1606 |

|

| Rear tread (mm) |

1587-1607 |

|

| Interior | ||

| Headroom front/rear (mm) |

999/978 |

|

| Shoulder room front/rear (mm) |

1414/1399 |

|

| Max legroom front/rear (mm) |

1100/906 |

|

| Luggage compartment-vda (litres) |

385 |

|

| CORROSION PROTECTION | 24-stage paint and body protection process, including zinc pre-coatings for all exterior panels excluding the roof, optimised dip phosphate process, electrocoat corrosion protection, filler/surfacer and clear-over-base enamel topcoat, plus comprehensive cavity wax injection, PVC underbody coatings and stone protection. Thick PVC sealing beads for all flanges. Front plastic wheel arch liners, rear textile wheel arch liners, anti-scuff strips on inner doorsills and rear load sill. 12 years anti-perforation warranty. | |

| AERODYNAMICS | Fully optimized aero pack, including front splitter, side rocker mouldings, rear venturi and twin-element rear wing | |

| Drag Co-efficient (cd) |

0.38 |

|

| Front surface (A), m2 |

2.35 |

|

| Front / rear downforce |

-0.022 / 0.000 |

|

| Weights | ||

| Basic kerb (kg) |

1467 |

|

| Gross vehicle mass (kg) |

1860 |

|

| Payload (kg) |

543 |

|

| Roof load (kg) |

75 |

|

| Performance | ||

| Max speed (kph) |

263 |

|

| Acceleration (sec)0-100 km/h 50-100 km/h (in 4th. gear) |

5.9 5.3 |

|

| Fuel Consumption | ||

| Urban (ECE l/100 km)Extra Urban (ECE l/100 km) Combined (ECE l/100 km)CO2 - combined mode (g/km) | 13.4 (21.0 mpg)

7.0 (40.3 mpg) 9.4 (30.5 mpg) 225 |

|

POWER/ TORQUE: